Supporting the Future of Energy with Venture Global's Plaquemines LNG Plant

The Go-To Supplier for Industrial Piping Solutions

As the energy landscape evolves, key infrastructure projects like Venture Global’s Plaquemines LNG plant are pivotal in meeting global energy demands. Located in Plaquemines Parish, Louisiana, this state-of-the-art facility is set to commence LNG production by mid-2024. The Plaquemines LNG plant is a prime example of an industry where Tubespec’s products would be a great fit. Our extensive range of products is essential for robust and reliable construction, maintenance, and repair, now and in the long term.

Since its founding in 1989, Tubespec has established itself as a leader in the distribution of hot-dipped galvanized steel pipes and fittings. With over four decades of experience, our founders have built a company known for its high-quality products and exceptional service. Tubespec’s products are applicable to a wide range of industrial industries, providing robust, durable, and reliable solutions for various applications. One notable example of how Tubespec’s products can be an excellent fit is the Venture Global Plaquemines LNG plant.

Plaquemines LNG: A Milestone in Energy Production

Venture Global LNG’s Plaquemines plant is a significant addition to the U.S. LNG export capabilities. With an expected capacity of 20 million tonnes per annum (mtpa) upon completion, the project is being developed in two phases. The first phase, decided in May 2022, includes a 13.3 mtpa capacity and related pipeline infrastructure. The second phase, sanctioned in March last year, will further expand this capacity and involves substantial project financing totaling $21 billion for both phases.

This plant is a part of Venture Global’s strategic growth, aiming to re-export LNG and enhance the global supply chain. The construction includes 36 modular liquefaction units, designed and shipped from Baker Hughes’ facility in Italy, ensuring cutting-edge technology and efficiency. The superiority of hot-dipped galvanized piping products lies not only in their resistance

to corrosion but also in their versatility and longevity. These pipes can withstand extreme

temperatures, fluctuating environmental conditions, and abrasive substances, ensuring

uninterrupted performance even in the harshest of settings.The facility also features robust storage solutions, with four large LNG storage tanks constructed in phases by McDermott’s unit CB&I.

The strategic importance of the Plaquemines LNG plant cannot be overstated. With the global energy market increasingly looking towards cleaner fuel alternatives, LNG plays a crucial role in bridging the gap between traditional fossil fuels and renewable energy sources. The Plaquemines plant will significantly bolster the U.S.’s LNG export capacity, positioning it as a key player in the global energy market.

Tubespec's Potential Role in the Plaquemines LNG Plant

Our products are known for their durability, corrosion resistance, and reliability, making them ideal for the demanding environments of LNG facilities. Tubespec’s products are readily available from any of their nationwide base of distributors.

Key Products Supporting LNG Infrastructure

Seamless Pipe Nipples: Essential for creating strong, leak-proof connections in the LNG plant’s extensive piping systems. Our seamless pipe nipples ensure that all connections are robust and capable of withstanding the high pressures and temperatures associated with LNG processing.

Forged Steel Fittings and Flanges: Provide robust joints capable of withstanding high pressure and temperature variations, critical in the LNG processing environment. These fittings and flanges are integral to maintaining the integrity of the plant’s piping infrastructure, ensuring safe and efficient operation.

Weld Fittings & Reducers: Ensure smooth transitions and flow management within the plant’s pipeline network. Proper flow management is essential in an LNG facility to ensure optimal performance and prevent bottlenecks in the system.

Swages and O-Lets: Used for reducing pipe sizes and connecting branches, ensuring flexibility and scalability in the plant’s operations. These components are vital for adapting the pipeline network to meet changing operational requirements and facilitate future expansions.

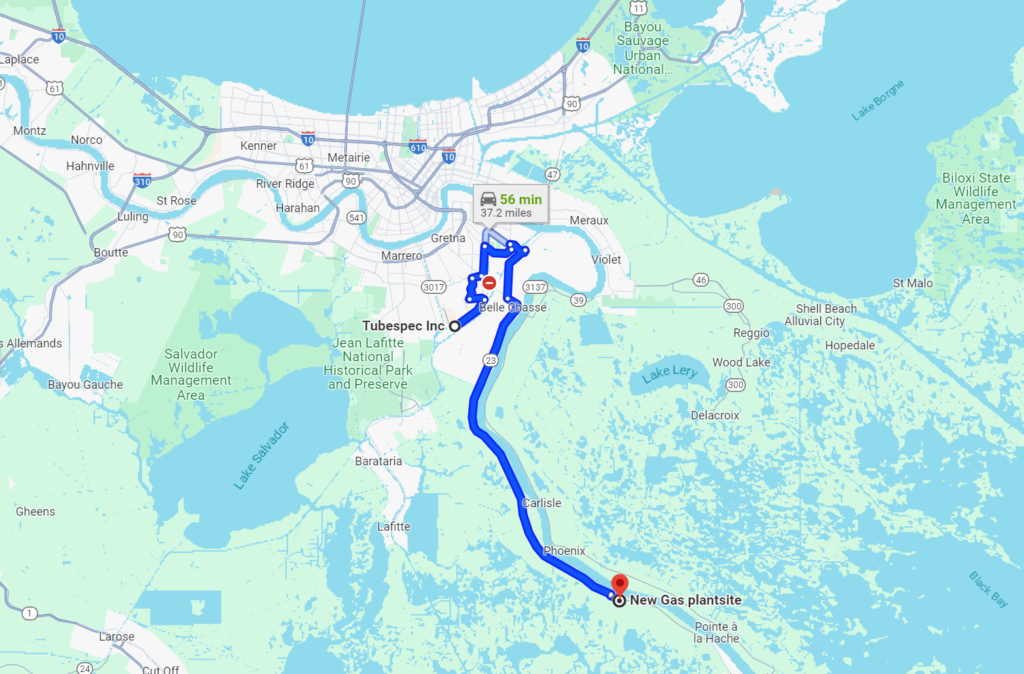

Proximity Advantage: Fast Response for Maintenance and Repairs

Tubespec’s headquarters are conveniently located just one hour’s drive from the Plaquemines LNG plant construction site. This close proximity offers significant advantages for Venture Global LNG, particularly in terms of emergency repairs and regular maintenance. Our strategic location allows us to provide swift, on-site support and timely delivery of essential piping products, ensuring minimal downtime and optimal operation of the plant.

In the event of unforeseen issues or urgent requirements, Tubespec can rapidly dispatch the necessary materials and expert personnel, mitigating the impact of any disruptions. This logistical advantage ensures that the Plaquemines LNG plant remains operationally efficient and resilient. Our ability to quickly respond to the plant’s needs is a testament to our commitment to customer service and operational excellence.

Extensive Inventory and Quality Assurance

Tubespec maintains a vast and comprehensive inventory of hot-dipped galvanized steel pipes and fittings, allowing us to meet the immediate needs of the Plaquemines LNG project. Our extensive stock ensures that we can supply materials promptly, supporting both the construction phase and ongoing operational requirements.

Quality is at the core of Tubespec’s offerings. We provide Material Test Reports (MTRs), Galvanizing Certifications, MSDS sheets, and Certificates of Compliance upon request, guaranteeing transparency and quality in every shipment. This commitment to quality assurance ensures that all materials supplied to the Plaquemines LNG plant meet the stringent standards required for such a critical infrastructure project.

Proximity Advantage: Fast Response for Maintenance and Repairs

Tubespec’s headquarters are conveniently located just one hour’s drive from the Plaquemines LNG plant construction site. This close proximity offers significant advantages for Venture Global LNG, particularly in terms of emergency repairs and regular maintenance. Our strategic location allows us to provide swift, on-site support and timely delivery of essential piping products, ensuring minimal downtime and optimal operation of the plant.

In the event of unforeseen issues or urgent requirements, Tubespec can rapidly dispatch the necessary materials and expert personnel, mitigating the impact of any disruptions. This logistical advantage ensures that the Plaquemines LNG plant remains operationally efficient and resilient. Our ability to quickly respond to the plant’s needs is a testament to our commitment to customer service and operational excellence.

Extensive Inventory and Quality Assurance

Tubespec maintains a vast and comprehensive inventory of hot-dipped galvanized steel pipes and fittings, allowing us to meet the immediate needs of the Plaquemines LNG project. Our extensive stock ensures that we can supply materials promptly, supporting both the construction phase and ongoing operational requirements.

Quality is at the core of Tubespec’s offerings. We provide Material Test Reports (MTRs), Galvanizing Certifications, MSDS sheets, and Certificates of Compliance upon request, guaranteeing transparency and quality in every shipment. This commitment to quality assurance ensures that all materials supplied to the Plaquemines LNG plant meet the stringent standards required for such a critical infrastructure project.

Long-Term Benefits of Partnership

Partnering with Tubespec offers long-term benefits for Venture Global LNG. Our products are designed to withstand the harsh conditions of LNG processing and transportation, ensuring the longevity and reliability of the plant’s infrastructure. By choosing Tubespec, Venture Global LNG can rely on a steady supply of high-quality materials that support both current construction needs and future maintenance and expansion projects

Nationwide Reach

In addition to our proximity to the Plaquemines LNG plant, Tubespec’s extensive distribution network enables us to ship to all regions of the continental United States. This ensures that our products reach various project sites quickly and in optimal condition, supporting the smooth progression of construction and commissioning phases across the country.

Our nationwide reach also means that we can support other LNG projects and industrial applications, providing the same high level of service and quality that we offer to the Plaquemines LNG plant. Whether it’s for new constructions or maintenance of existing facilities, Tubespec is equipped to meet the diverse needs of our customers.

Conclusion

The Plaquemines LNG plant represents a significant advancement in the global LNG market, and Tubespec is ideally positioned to contribute to its development with our high-quality galvanized steel products. Our strategic proximity to the plant, combined with our extensive inventory and commitment to quality, makes us a valuable potential partner for Venture Global LNG. As the Plaquemines plant prepares to commence production, Tubespec’s reliable piping solutions will play a crucial role in ensuring the plant’s infrastructure meets the highest standards of safety and efficiency.

For more information on how Tubespec can support your industrial projects, visit our website or contact our expert team today. With Tubespec, you can trust that your project is in capable hands, supported by decades of industry experience and a dedication to excellence. Partnering with Tubespec will ensure that Venture Global LNG’s Plaquemines plant operates smoothly and efficiently, both now and in the future.

Tubespec’s products are readily available from any of their nationwide base of distributors.